The Difference Between Traditional and Rapid Molding

By Leslie Langnau, Design World

Rapid molding is a key player as the “digitization” of nearly every process to make products continues. The latest industry to experience this shift is molding. Here’s a look at how digitization may affect traditional molding service providers.

Pierre Viaud-Murat | Senior Vice President of Sales

Digital manufacturing offers many benefits across multiple touch points: it can reduce time to market, labor overhead and asset use, plus it helps customers control quality and inventory. These advantages allow users to explore new revenue streams, develop and enhance innovative designs and respond to market demands. The digital age can enhance designers freedom to create and develop through one streamlined methodology.

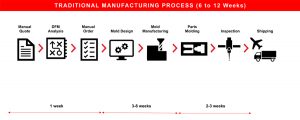

The traditional manufacturing process

The traditional manufacturing process usually consists of a several-step sequence within the manufacturing flow. Team members monitor and ensure that safeguards are in place throughout the entire part lifecycle. Throughout the process, various testing for form, fit and function are required to discover any part flaws. Each team member should be aware of these critical-path processes, as the traditional method of manufacturing requires more manual than automated production.

The traditional injection molding manufacturing process usually consists of several steps. Throughout the process, various testing for form, fit and function are required to discover any part flaws. Usually, the traditional method of manufacturing requires more manual than automated production.

For example, generating a quote using a DFM analysis and confirming an order manually can take approximately a week, if all of the process steps are accurate and on track the first time through. In the event that any modification is required, the same process steps would be repeated before finalizing the order.

Once an order has been placed, the mold design is reviewed for viability. When that design is finalized, it will go onto the next phase of the traditional manufacturing process. This can be a lengthier portion of the process, ranging from three to eight weeks. Additional delays may also occur if project issues are not identified early in the quoting process, which will result in re-quoting, redesigning or redefining the project. Any of the three can result in significant delays.

With all of the production factors in place, the part will then be molded. After the first shots, a visual and dimensional inspection will be done. If the part passes inspection, it is shipped out to the customer for review and feedback.

Once the customer inspects the part, they have the opportunity to approve or reject the run. In the event of a non-approval, the process would be modified and revisited again with continual iterations until the optimal part is achieved. Any combination of these factors can impact the cost, quality and timing in a traditional manufacturing process.

The digital manufacturing process

Another approach to injection molding involves the digitization of as many injection-molding steps as possible. This approach is referred to as rapid or digital manufacturing, and is a natural progression of traditional manufacturing. The streamlining possible by digitizing many traditional molding steps can reduce total costs.

An evolution of traditional injection molding manufacturing is referred to as digitization. It involves digitizing as many injection-molding steps as possible to streamline many traditional molding steps to reduce total costs.

Digital manufacturing begins with the upload of a 3D CAD file to a service provider’s servers. The geometry and part requirements are analyzed, usually with proprietary software. Then the customer receives an interactive quote. Once the customer approves the quote, an order is generated and the mold design finalized and a tool-path created, often within hours.

The initial mold can often be created with modular components, which is another cost savings. Then, the mold is usually machined, a process that takes a couple of days. After benching and finishing, the mold tool is assembled for first production shots and inspection.

This process of rapid mold development can shorten development lead-time to weeks instead of months.

Digital manufacturing can accelerate every step of a part creation process. In traditional manufacturing, the retooling investment could push the break-even manufacturing numbers into the thousands – a cost-prohibitive change for many smaller businesses. Digital manufacturing, however, can implement that small design change for approximately a quarter of the investment in a quarter of the time.

Digital manufacturing is scalable and flexible. Should demand rapidly increase, the digital manufacturing process can move between low-volume to mass production. Thus, designers can react to market behaviors quickly and easily. If demand drops, rapid manufacturing enables adjustments while still achieving the lowest total cost. Thus, regardless of a market’s volatility, digital manufacturing lets users respond accordingly.

The digital manufacturing process allows customers to quickly go through multiple iterations easily. Low-cost tooling makes low-production runs economical enough to test on select markets and use the feedback as a learning curve. Customers can maintain their existing quality controls, while developing good parts that can get to market faster. Some service providers offer optional services, such as inspection and project management consulting. Digital inspection allows for rapid feedback and tool modifications, if necessary. Service providers usually have experienced tooling experts who can consult during the mold development process to solve any problems that arise.

Mold considerations

Mold service providers strive to ensure a mold tool is available over the lifecycle of a project. Often, the tool is made from a high-grade aluminum base material, like QC-10, which offers an excellent strength-to-weight ratio.

Compared to steel, aluminum is softer and less dense, dissipates heat quickly and efficiently and costs up to 75% less. It’s also a recyclable material, an attractive feature when material waste can be higher than 50% per part. Recyclability and material reuse can help recoup initial material costs.

Although aluminum may not be the right material for every type of mold, it works well for prototyping, bridge tooling and low volume production. Depending on the size and structure of the parts, the heat dissipation within an aluminum mold can be up to 50% higher than steel or other metals, creating faster production turnaround times. Aluminum molds will usually last through production runs of several thousands of parts. DW.

The article above is featured in Design World’s Make Parts Fast.

If you would like additional information on the rapid molding process, contact one of our Technical Specialists today at 586-598-4636 or sales@xcentricmold.com.