Celling Biosciences Receives Complex Plastic Parts in 30 Days

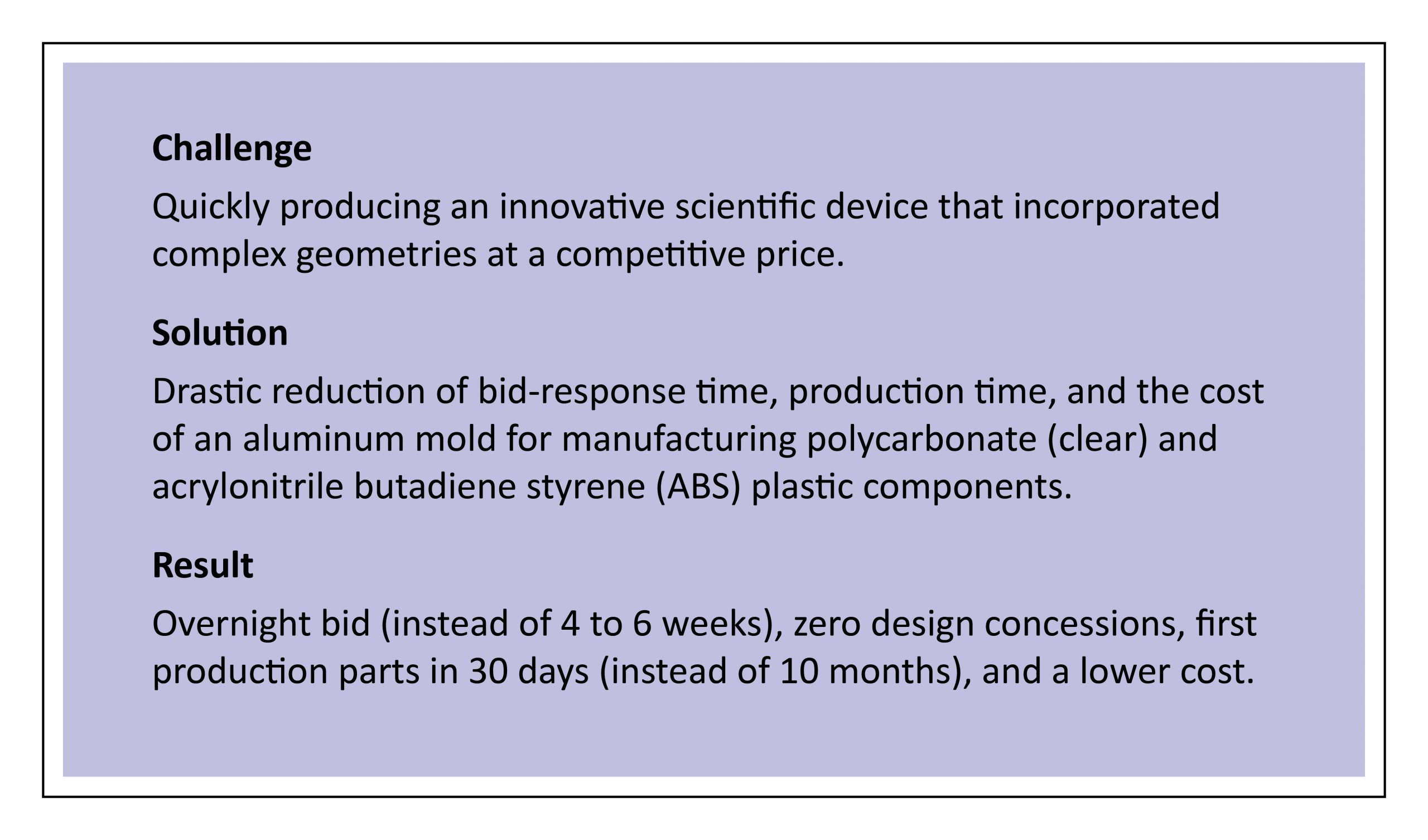

Medical and scientific devices pose three key challenges for companies like Celling Biosciences: time, quality, and cost. On one hand, to build a reputation for leadership in the closely watched biotech industry, you have to launch innovative products before your competitors can do likewise. On the other hand, if you can’t manufacture high-quality injection molding parts with complex geometries at market acceptable prices, you lose to those who can. Those were the concerns of Celling Biosciences’ engineering team in Austin, Texas when they sought for competitive bids to manufacture parts for a new clinical blood-therapy device.

Complex Geometries Are Difficult to Produce

In late 2017, Medical Design Engineer Jay Jones was issuing bid packages for this project. He had identified three competent parts manufacturers. Among them was Xcentric Mold & Engineering. He first heard about Xcentric from a colleague: “You just have to try them,” he was told. And by late 2017, he had already used Xcentric on more than one occasion to successfully produce parts that incorporated increasing levels of design complexity. But now he had something that was very difficult produce. Celling Biosciences’ new blood-processor — called the Autologous Regenerative Therapies (ART) Two-Step Platelet Rich Plasma (PRP) device — had all the hallmarks of a serious production challenge.

Jay had reduced the number of components in the design from 23 to 8 but making some of these parts would not be easy. One mold was quite simple, producing the orange thumb wheel positioned on the top of the final product. The mold for the transparent base component, however, incorporated geometries requiring complex mold features such as threaded inserts, slides, and multiple hand loads — the stuff any engineer would acknowledge as a real test for an injection molded parts supplier. Accuracy, quality, and adherence to tight tolerances were absolutely necessary to create a final product that clinical labs would buy and rely on for day-to-day safe and reliable operation

Overnight Quote and Injection Molded Parts in 30 Days

The team at Celling Biosciences also understood the impact of launch dates on profitability. Their existing parts suppliers would normally take from four to six weeks to develop a quote in response to a bid package. Although that kind of lead time is built into a typical product launch by medical device companies, it doesn’t help the bottom line, and nobody has to like it. Other suppliers would decline or request multiple concessions on complex designs. So after uploading their design files to three bidders, the team was astonished when Xcentric responded overnight with a bid and zero design change requests.

By comparison, one of the other two bidders responded in four weeks, and the last bid came in after six weeks had passed. So on the bid process alone, Xcentric had saved Celling Biosciences a significant amount of lead time. But that wasn’t the end of the story.

After conferring with his colleagues at Celling Biosciences, Jay accepted the bid from Xcentric Mold & Engineering. The contract called for the creation of aluminum molds and production of parts made from a PC/ABS blend. Expectations were for a low- to mid-volume production flow, around 3,000 parts per year.

Figure 1. The ART Two-Step PRP

This was the first time that Celling Biosciences had awarded a product with such complex geometries to Xcentric Mold & Engineering, so Jay had the usual sense of anticipation about delivery of the final product. His previous experiences with Xcentric, however, had been excellent, and he was confident that they would be able to handle the complex geometries in the ART Two-Step PRP. But he was unprepared for the fast production turnaround. Xcentric delivered the “first shots” (the first production parts) to his office within 30 days — including delivery time! Jay put it into his own words: “I was holding the finished product only a week after the second bidder sent a quote and two weeks before the last bidder responded! It’s the kind of timetable nobody in the industry can match.”

Complex Geometries at the Right Price

Despite the complex geometries of Jay’s design, Xcentric had fulfilled its promise of a fast turnaround for customers:

“No matter the complexity of your design or the quantity of your order, Xcentric can deliver a wide variety of plastic and metal custom parts in as fast as 1-15 days.”

The final success factor was the low cost of the Xcentric bid. The company had delivered a complex, high-quality product at a lower cost than competing bidders, while maintaining the whole production chain in the United States. Taken as a whole, Xcentric helped Celling Biosciences bring a complex product much earlier to commercial stage and within budget.

If you are interested in receiving more information, contact us at sales@xcentricmold.com or 586-598-4636.

For more information on injection molding, click injection molding .