Rapid Digital Manufacturing: Linking Plastic Injection Molding To The Global Supply Chain

Digital manufacturing is critical for achieving one of the post-pandemic goals: a robust and sustainable supply chain. One that can maintain the flow of business in any global climate.

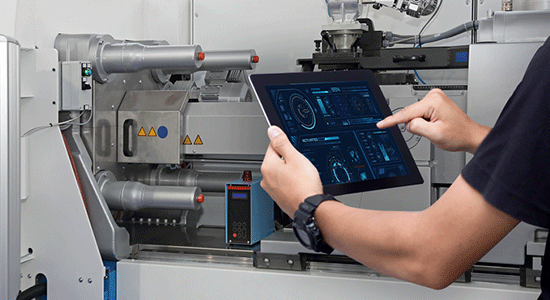

This is because it links all areas of production. Digital manufacturing uses technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) to connect services, supply chains, products, and processes.

In doing so, it provides greater visibility into the entire supply chain. And this level of insight helps companies to identify (and predict) potential kinks in the supply chain.

Essentially, smarter manufacturing.

And now, as we emerge from a global pandemic that exposed alarming weaknesses in the supply chain, we are finding new ways that digital manufacturing can enable a robust supply chain.

For example, choosing a rapid manufacturing partner that leverages digital manufacturing. Never thought about digital manufacturing and your manufacturing partners in the same sentence? Think again.

What is rapid manufacturing?

Rapid or digital manufacturing is a natural progression from traditional manufacturing. The capabilities afforded by digitization, automation and data connectivity translate into reduced costs, and increased efficiencies. These capabilities can even be used in injection molding.

So how does it work? Each process step is streamlined to accommodate quicker turnaround times with low-cost automated solutions.

Digital manufacturing process for plastic injection molding

The process is entirely digitized. First, request a custom injection molding quote and upload a 3D CAD file onto our servers. Next, part geometry and requirements are analyzed using our proprietary software. Then, an interactive quote is available online.

Upon approval an order is generated and the mold design is finalized within hours – together with the toolpath programming.

Using modular construction and standardized components, mold components are then machined, usually within a few days. After benching and mold finishing, the tool is assembled for first shots and inspection.

This process, achieved through rapid molding, will give your part a lead time of weeks instead of months. The average price? A fraction of the cost for traditional molding.

The capacity that’s available for you to get your part made? Your lead time is always the priority. It’s made in the USA with as many sourced mold materials and resins that can be procured in the allotted time.

As a result, digital manufacturing naturally accelerates every step of the process and reduces the labor intensity while driving the scale of your project.

Learn how mold flow analysis can help to optimize the process before production begins.

Digital manufacting: scale production to meet market demand

Post-COVID-19 we are faced with uncertainties in the market. Digital manufacturing enables us to scale production to help you meet market demand.

For example, consider a complex syringe. It may consist of three, distinct injection-molded parts. Before new production runs are needed to meet supply and demand, the product manager may have a revision to one of the components, driven by departmental standards.

In traditional manufacturing, the retooling investment may push the break- even manufacturing numbers into the thousands – a cost-prohibitive change for many smaller businesses. Digital manufacturing, in comparison, can implement that small design change for approximately a quarter of the investment in a quarter of the time.

Our unique ability to accommodate complex designs is our asset

Your designers have fewer roadblocks, freeing them to work on new projects instead of going back to the drawing board to modify their designs so they can be produced.

Rapid results let your team respond quickly to market requirements with the best product they can design – a competitive edge that keeps your company on top. Without design rework or months-long lead times, innovation can boost your company’s results.

Two optional digital manufacturing services: inspection and project management

The digital manufacturing process at Xcentric is a very rapid and seamless process. The key components of this process include cost, quality, automation and speed to market, which allows customers to go through the iteration process once or numerous times, if necessary, at a very quick speed. By following these steps, customers can maintain their existing quality controls, while developing good parts getting them to market faster.

There are two optional services in this process: inspection and project management.

Digital inspection allows for rapid feedback and tool modifications, if necessary. Experienced Tooling Engineers interface directly with designers during the entire process, providing expert advice and problem solving at any time, which is critical to ensure successful and fast product manufacturing.

In fact, shorter lead times from concept to development can create new-market discoveries. Previously untapped revenue streams that were potentially out of reach can be viable, thanks to new technologies, transforming how companies like yours do business.

Low-cost tooling, development and production have been streamlined so low-production runs are economical enough to test on select markets and use the feedback as an optimized learning curve.

Should demand rapidly increase, the rapid manufacturing process can transition between low-volume to mass production. In turn, that allows you to react to market behaviors quickly and easily, reduce your time to market for increased competitiveness and resolve any potential problems before they impact your shipments.

In instances where production inadvertently slows, rapid manufacturing allows you to make adjustments while still achieving the lowest total cost. That means regardless of the market’s volatility, rapid manufacturing lets you respond accordingly.

Digital manufacturing offers benefits across multiple touchpoints: reducing your time to market, labor overhead and asset utilization, giving you more opportunities for quality control and inventory management. These advantages allow you to explore new revenue streams, develop and enhance innovative designs and respond to market demands. The digital age can transform your company and give your designers the freedom they need to create, develop and enhance in one streamlined methodology. The future is here. Make it work for you.

Working on a project?

Let us help you get that first prototype underway and have that part in your hands in as few as five days. Our engineers help you through the design process. Get your project started now!