However, there is an upfront cost involved as integrating these features into a custom plastic injection molded part can be quite extensive. Consider the following when integrating living hinges, snaps, and clips to your plastic parts:

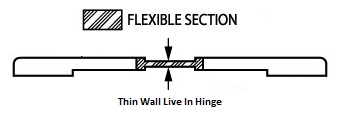

Living Hinges

Living hinges are a great way to marry two halves of a component together. However, it should be noted that living hinges are not meant for multiple use or continuous duty. Make sure that the material selection for your part supports living hinges. Many materials cannot flow through the thin wall section of the hinge thus causing the part to not be moldable. Living hinges also require plastic materials that can remain flexible when they are molded into thin wall sections. Otherwise, your living hinge may crack and fail on first use.

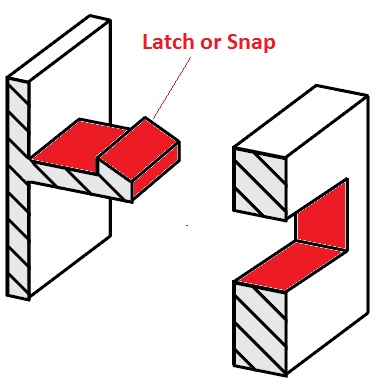

Snaps and Clips

Snaps and clips are a great way to eliminate screws in the assembly of your project. When incorporating snaps, consider the tooling cost of these features. Often these features cause your part to have undercuts. Undercuts require additional tooling costs—costs that can add up quickly when multiple clips are integrated into your design. Where snaps and clips are concerned, there is also a risk of sink if proper guidelines are not followed. For low-volume projects, the traditional screw and boss are still the most affordable approach to assemblies.