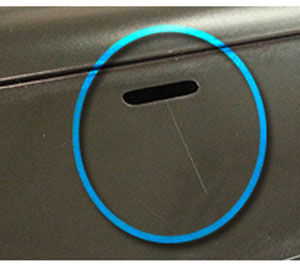

As the plastic travels through the cavity it wants to naturally cool. This is because the melt temperature is much higher than the mold temperature usually between 150 -300 degrees Fahrenheit. To further complicate matters, if the molten plastic meets an obstruction it must travel around and meet at the other side. Obstruction are those that create windows or core outs in the part. See the illustration above. If the plastic has cooled too much during the injection process it can lead to knit lines in plastic parts when they meet past an the obstruction.

Some plastics are more prone to knit line than others. Usually materials with lower flow rates such as ABS are prone to knit lines.

Knit lines are most common downstream of holes created in parts where the molten material meets. While knit lines can be present it does not always mean the structural integrity of the plastic part is compromised.

It is important when selecting an injection molder that the right process conditions are used to reduce or eliminate the effects of knit lines in your plastic parts.

At Xcentric we use our proprietary process engine to reduce or eliminate knit lines as much as possible.