Material Selection for Injection Molding

Your choice of material becomes more critical the closer you are to production.

The same material used in each of the manufacturing process will produce different results. For instance, a part 3D printed in ABS will have very different strength and finish properties compared to a part machined via CNC. This is due to the process being used: additive (building a part layer by layer) vs. subtractive (cutting away a shape from a solid block of material).

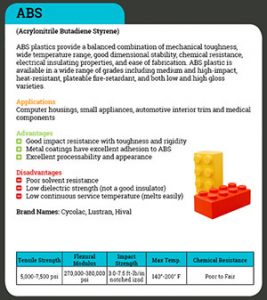

Because additive manufacturing is typically best used for prototypes where many of the qualities of a chosen material will matter less, we have put together a material guide for injection molding.

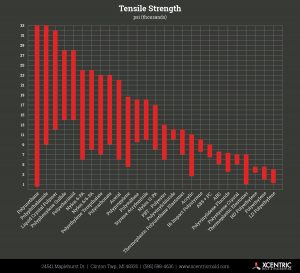

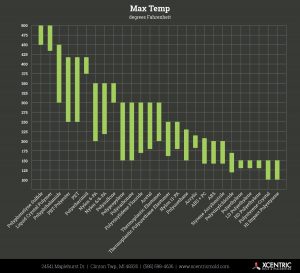

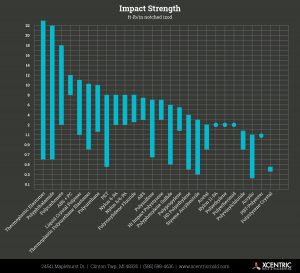

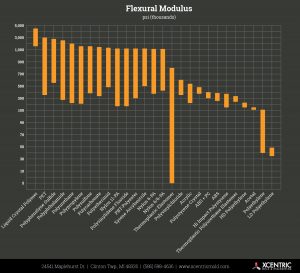

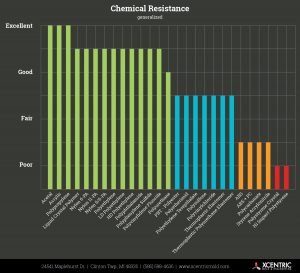

We cover some of the most common materials and include a general overview of things like tensile strength, impact strength and chemical resistance. Below are downloadable charts that lists materials in order of best to worst for each.

We hope this will help guide you to selecting the most appropriate material for your project.