Tool Offerings for Injection Molded Plastic Parts

At Xcentric, we provide prototype injection molding and low-volume injection molding services. Our streamlined prototype injection molding service can deliver first articles in as fast as five days.

Meanwhile, our low-volume production process frequently—and rapidly—delivers plastic parts for customers needing a few hundred to thousands of components as a bridge to higher productivity molds.

Which to choose?

Xcentric has a reputation for being able to handle everything from the simplest to the most complex projects, meeting overmolding, custom insert molding, and other complicated requirements. Choosing between prototype injection molding and low-volume injection molding comes down to your project.

- Do you need higher quantities of parts?

- Would you need lifetime maintenance for the mold used to make your part?

- What level of documentation do you require?

- What is your budget?

Xcentric experts, who are engineers just like you, will be able to advise you on the best choice for your project.

If you’re not sure which route to take, you can start with a prototype tool and then upgrade to low-volume production at a reduced cost and get your prototype tool for free.

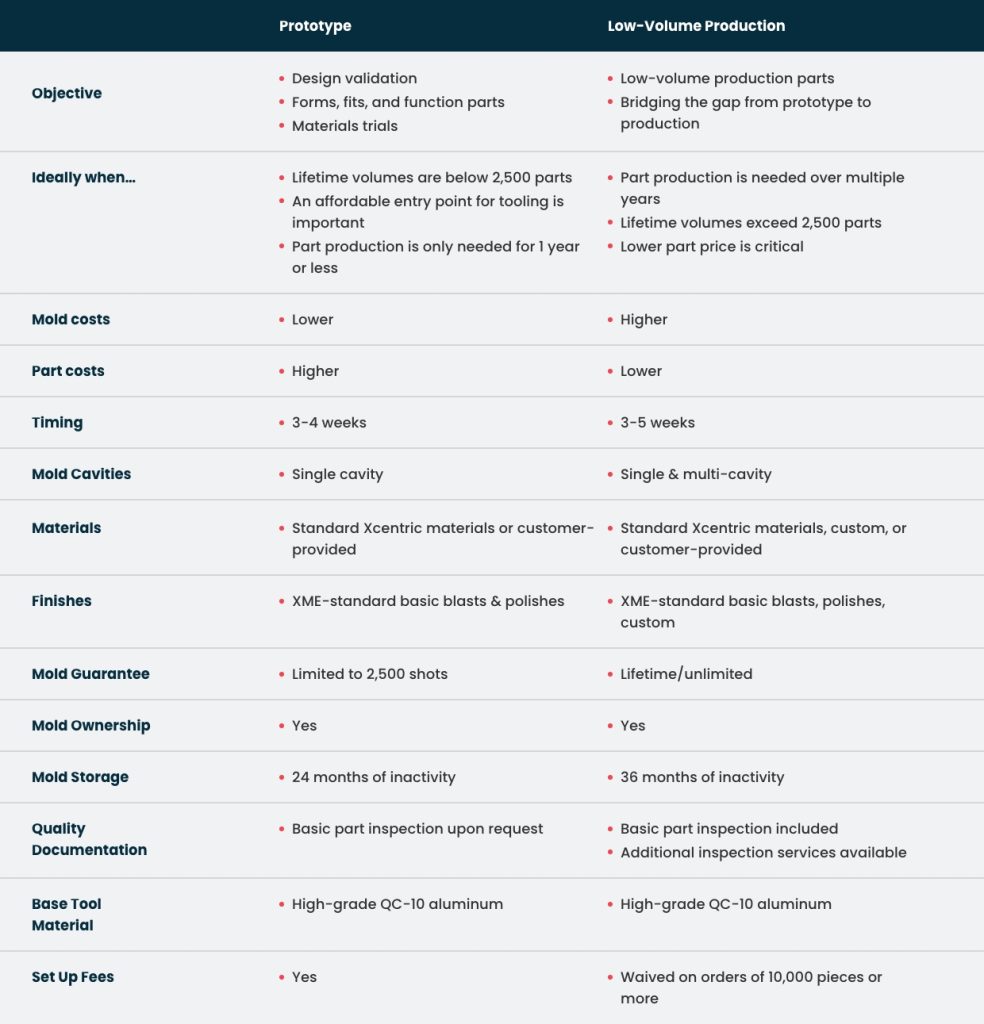

Comparison: Prototype vs. Low-Volume

How Does Low-Volume Injection Molding Work?

Firstly, our Design for Manufacturability process (DFM) will deliver feedback that can help you simplify, optimize, and refine your product design. This covers a variety of challenges, including design and suitable production processes, which affect manufacturability and performance.

Depending on your part’s application, design, material, and required production rate, we may suggest increasing the number of cavities. Then, we’ll apply the data and the learnings from the DFM to every stage of the production process.

Xcentric’s streamlined system allows us to routinely injection-mold high-grade parts in any production quantity faster and within your budget.

Xcentric is competitively priced for low- to mid-volume production.

We offer bridge tooling and Just-In-Time production in addition to standard production and dual sourcing.