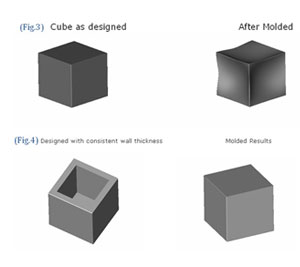

As the part cools the thick sections will shrink more than the thin sections. As a result the thin section will be pulled in toward the thick section thus resulting in warp. Additionally, if the part is informally thick it can cause sink issues and unstable dimension caused by excessive shrink.

Sink Marks in injection molding can also be caused by features adjacent to nominal walls. For example, if a wall has a rib or a boss protruding from it ant the width of the boss or rib is greater than 60% it can result in a witness or sink mark on the opposite side of the adjacent wall. The above illustration is a part that has 2 bosses on the reverse side. Bot of these bosses are larger than 60% of the wall section they are attached to. Causing sink marks on the reverse side of the part.