Designing Plastic Parts For Injection Molding? Run Mold Flow Analysis Before Cutting The Mold Mold flow analysis is not required for the injection molding

Search Results for: wall thickness

Design for Manufacturability ebook

Download our Smart Guide to Design for Manufacturability Learn How to Reduce Time and Cost: Injection Molding Basics The Basics of Molds and the

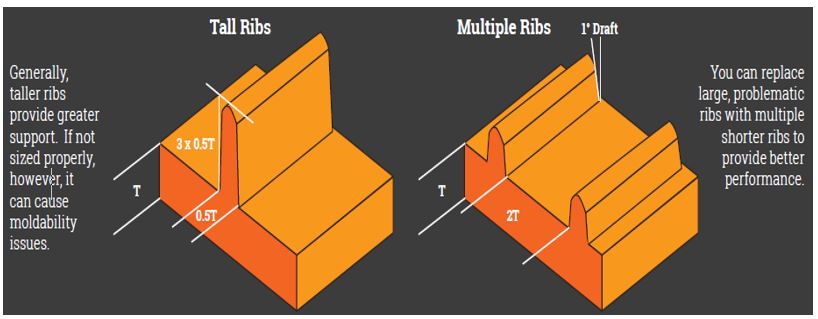

Use Ribs to Strengthen Plastic Injection-Molded Parts

Ribs are a feature in plastic injection molded parts. They are thin extensions that run perpendicular from a wall or plane. They are commonly used to provide additional support and strength to a part.

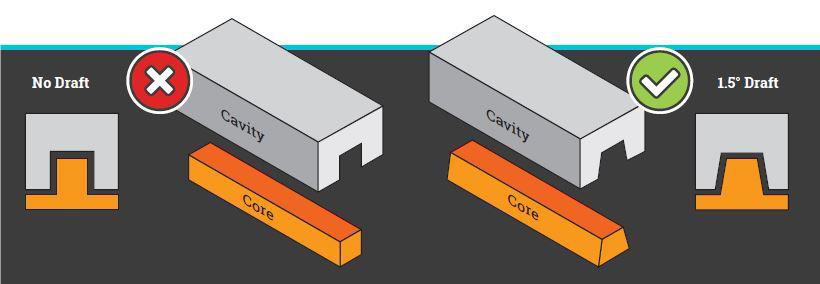

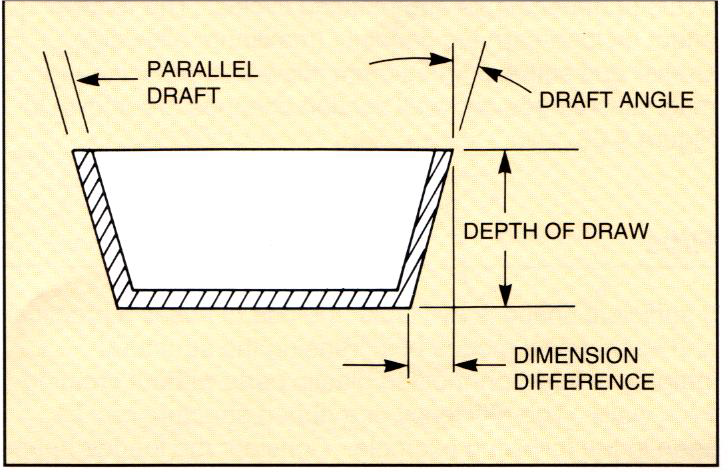

Draft Angles Can Improve Plastic Part Designs

Plastic parts should be designed with draft to prevent sticking and ejector pin push marks on the outward surface during ejection. Applying the proper draft angles or tapers on the surface of an injection molded part is critical to part moldability.

Designing for Plastics

The success of your plastic part relies upon many key elements working simultaneously. There are many factors that influence the outcome of your plastic part and should be taken into consideration when designing with plastics as follows:

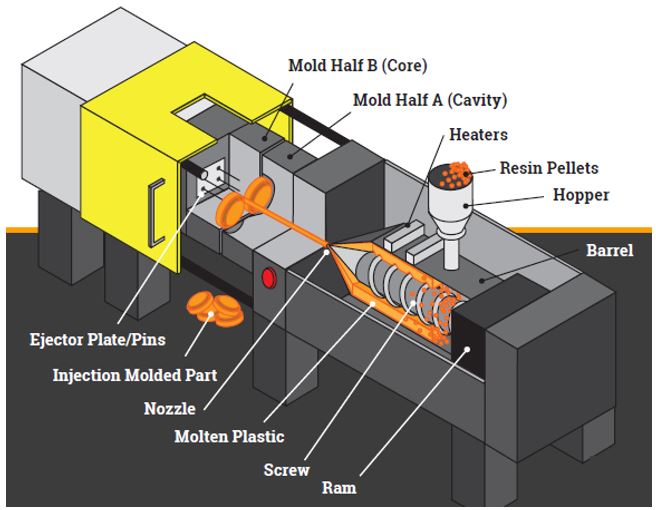

Adding Injection Molding Features to Your Part

Plastic resin pellets are loaded into the hopper, where it travels into the barrel of the injection molding machine. Through both heat and pressure, the plastic pellets are melted into a molten material that is ready to be injected. As the screw turns it creates pressure which will help push the molten plastic through the nozzle and into the mold.